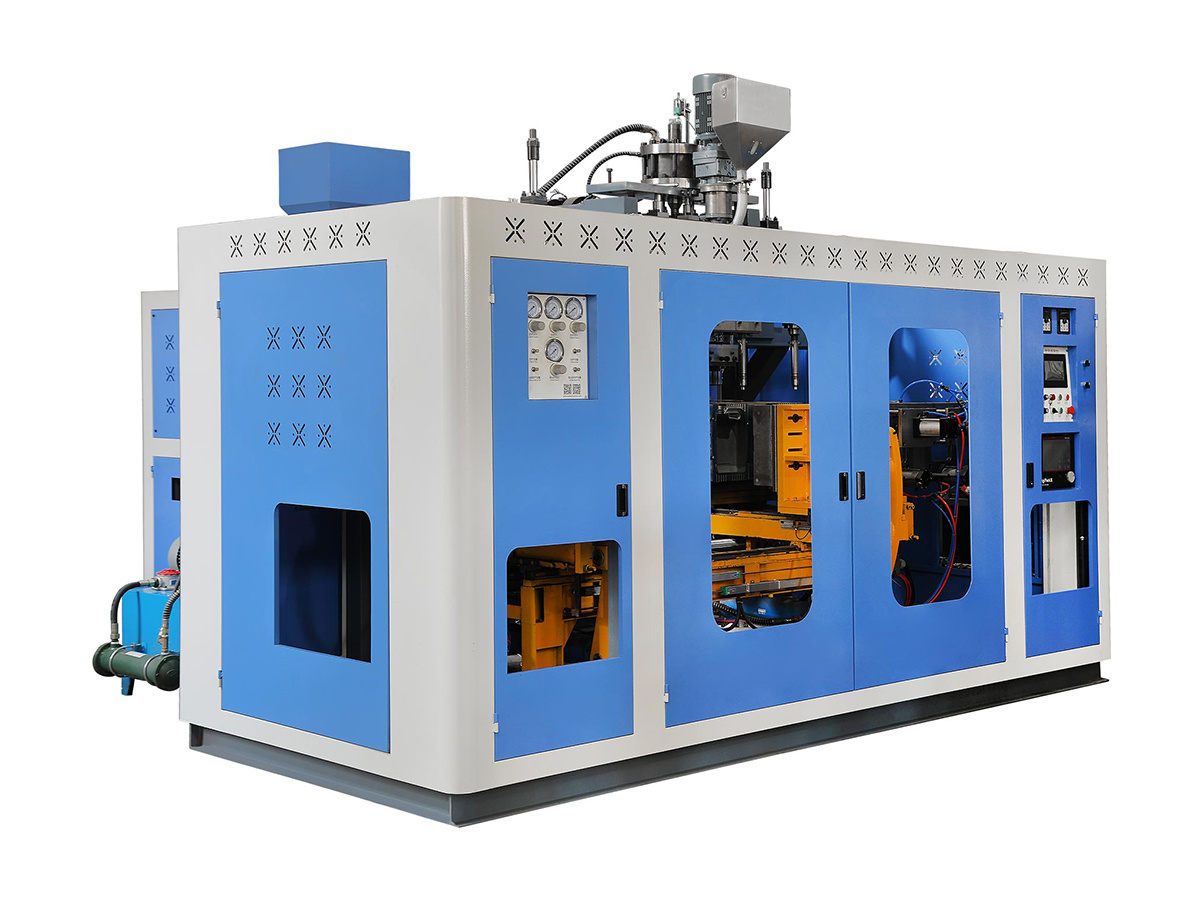

Fully automatic hollow blow molding machine

Suitable for 1L-12L oil cans, lubricating oil cans, detergent cans, etc.

Category:

Product Description

Technical Features

1. This general-purpose equipment is suitable for producing conventional hollow plastic products from 0.1ml to 30L. Different models with various structures can be selected according to different products.

2. FW1L to 5L series: This series is a pneumatic machine, lightweight, compact, clean, oil-free, and energy-saving.

3. FW1L to 12L series: Standard hydraulic model, stable, large mold capacity, economical adaptation, and easy operation.

4. FW0.5L to 30L series: Curved arm closure, even force distribution, beautiful seam, and versatile for 0.1ml-30L products.

5. FW1L to 30L Yitian series: Pure electric model, high-speed, energy-saving, environmentally friendly, noise reduction, clean and oil-free.

Technical Parameters

| Item | Item | Unit | 2L | 5L | 10L | 15L | 20L | 30L | 60L |

| Basic Specifications | Machine Dimensions | m | 3x2x2.2 | 3.7x2x2.3 | 4x2.86x2.5 | 4.5x3.3x2.8 | 5x3.8x3 | 6.5×6.3x2.5 | 7.6x7.3x4.6 |

| Machine Weight | T | 3.8 | 5.5 | 7 | 10 | 15 | 20 | 26 | |

| Extrusion System | Screw Diameter | mm | 55 | 70 | 80 | 90 | 100 | 100 | 120 |

| Screw L/D Ratio | L/D | 25 | 25 | 25 | 25 | 25 | 25 | 25 | |

| Number of Screw Heating Sections | pcs | 4 | 4 | 5 | 5 | 5 | 5 | 5 | |

| Screw Heating Power | kw | 11 | 12.6 | 17.6 | 17.6 | 17.6 | 22.4 | 30.2 | |

| Extruder Motor Power | kw | 11 | 18.5 | 22/30 | 30/37 | 45 | 55 | 90 | |

| HEPE Plasticizing Capacity | kg/hr | 50-70 | 70-85 | 100-120 | 130-160 | 180-220 | 160 | 280 | |

| Die Head | Number of Die Head Heating Sections | pcs | 3 | 4 | 4 | 5 | 5 | 5 | 5 |

| Maximum Die Diameter | mm | 90 | 160 | 160 | 220 | 220 | 260 | 350 | |

| Mold Opening and Closing System | Mold Opening and Closing Stroke | mm | 200-400 | 200-480 | 220-500 | 260-600 | 370-800 | 360-850 | 450-1050 |

| Opening Distance | mm | 200 | 180 | 180 | 340 | 430 | 190 | 600 | |

| Clamping Force | kn | 50 | 100 | 100 | 160 | 190 | 200 | 365 | |

| Maximum Mold Size | wxh | 300x350 | 400x420 | 450x460 | 500x500 | 600x620 | 700x980 | 800x1050 | |

| Cooling Water Pressure | mpa | 0.3 | 0.3 | 0.3 | 3 | 0.3 | 0.3 | 0.3 | |

| Oil Pump Motor Power | kw | 7.5 | 11 | 11 | 12 | 15 | 15 | 18.5 | |

| Energy Consumption | Total Machine Power | kw | 40-43 | 50-60 | 62-72 | 88-93 | 91-97 | 110-120 | 120-130 |

| Blowing Pressure | mpa | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.8 | |

| Air Consumption | L/min | 0.5 | 0.5 | 0.6 | 0.7 | 0.7 | 0.8 | 1 | |

| Water Consumption | L/min | 50 | 60 | 60 | 60 | 70 | 70 | 90 |

Model Description

This series of models can be optionally equipped with functions such as electric mold shifting, servo oil pump, wall thickness controller, and transparent line. Parameters will be adjusted accordingly;

The above data is for reference only. Our company reserves the right to modify the mechanical structure. The relevant content involved in purchasing equipment shall be subject to the contract.

Keywords:

blow molding machine

Related Products

Welcome your message consultation

Have a question? Stay in touch. We'd love to hear from you.